Operation:

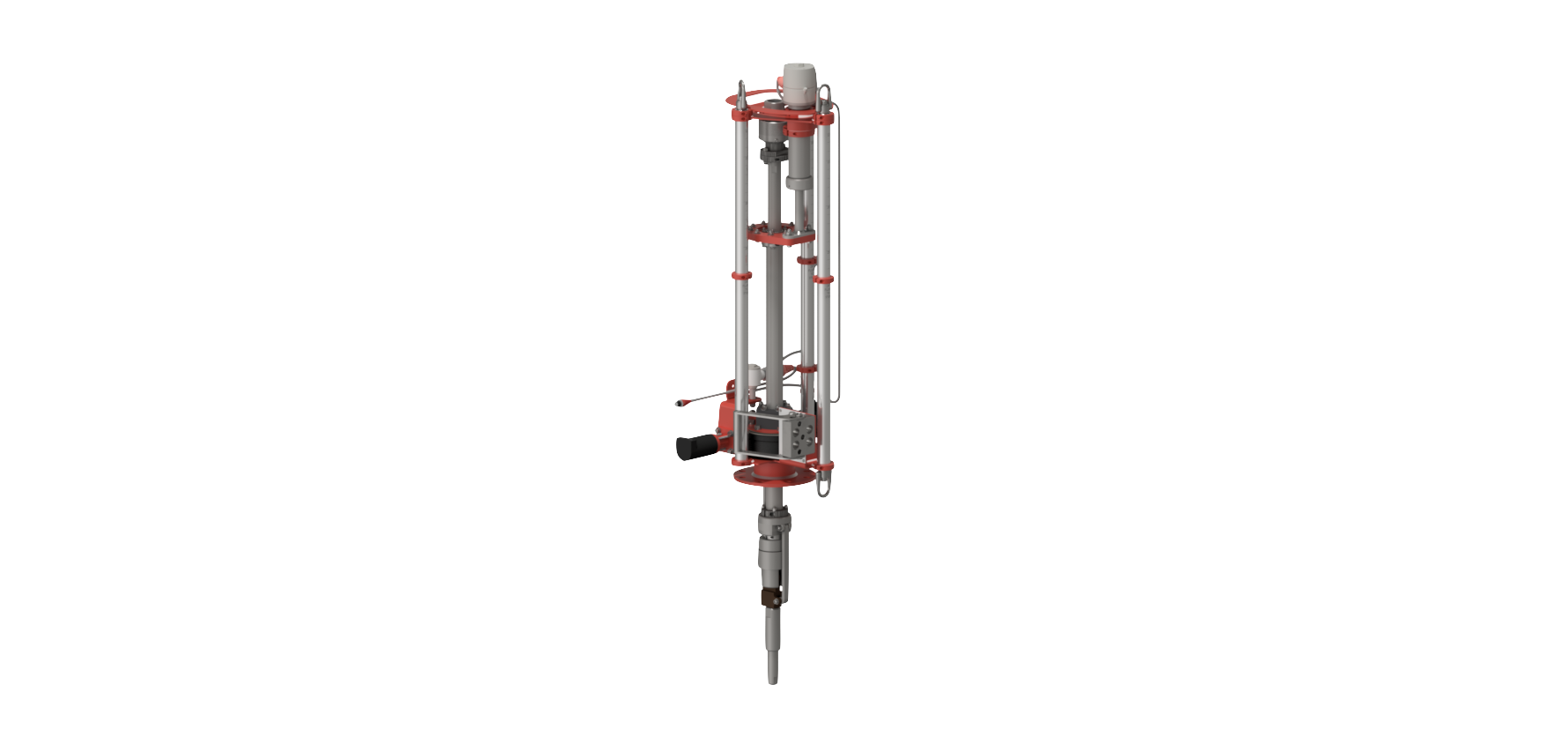

- Removes product from process vessels by attaching to any nozzle 4” and up.

- Can be dropped through a floating roof leg for product removal in strategic spots within a tank.

- Flow control option available

- Powered and operated by Mini Control Station or Command Center

- 360 degrees rotational axis

- Articulating arm has 90 degrees of tilt

- Can be mounted in any orientation

- Interchangeable high flow, low pressure and low flow, high-pressure nozzles to cover both debulk and final cleaning

- Nozzle can also be switched for varying lengths depending on vessel/tank size.

- Extends from 12″ to 32″ into a tank or vessel

Industry-Leading Performance:

- Heated hydraulic circulation loop provides optimal performance in cold weather

- Caustic resistant

- Supports manual and automated operation

Rig-Up and Installation:

- Single-person rig-up and installation

- Hand-portable

- 2-piece design for ease of installation

- Operates with two 3/8″ hydraulic lines and data cable

- Nozzle can be switched out to varying lengths depending on vessel/tank size.

- Ultra-light 300 foot data cable

- Daisy chain hydraulic and data connections to additional tools

Specs:

- Dimensions & Weight:

- Nozzle Section:

- Automation Spool:

- Combined:

- Low Pressure, High Flow Nozzle:

- High Pressure, Low Flow Nozzle:

- Class I, Division 1, Groups C and D for Canada & USA

- ATEX Zone 0 Certified

- Click here to view the 3D model