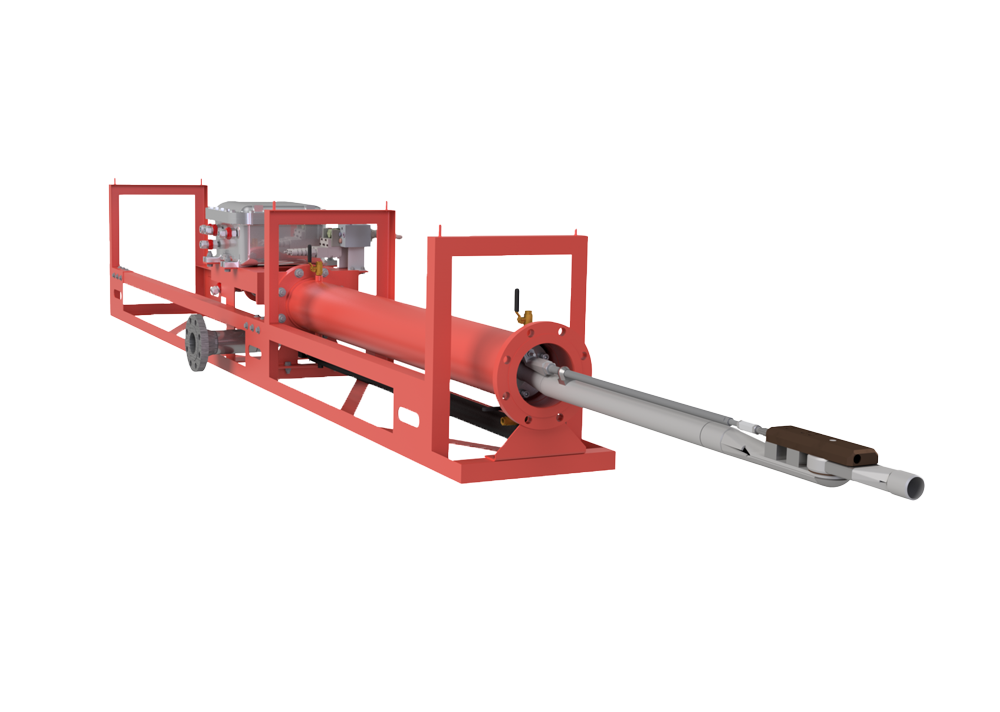

Tank Sweep

Operation:

Powered and operated by Mini Control Station or Command Center Sealed injection into full tank 180 degrees on single axis Effective range: 80 – 100 feet Horizontal operation Manual or automated control

Number of Sweeps Recommended:

The number of tank sweeps recommended depends on the tank diameter

2 tank sweeps for tanks up to 160 ft in diameter 3 tank sweeps for tanks with diameters between 160 – 260 ft 4 tank sweeps when the tank has a diameter greater than 260 ft

Industry Leading Performance:

Nozzle Exit Velocity: 400 ft/s 1:1 Fluid to Solids Ratio Heated hydraulic circulation loop provides optimal performance in cold weather

Rig-Up and Installation:

Single-person rig-up and installation Balanced lifting lugs on sweep for easy installation Operates with two 1/2″ hydraulic lines and data cable Daisy chain hydraulic and data connections to additional tools

Specs:

Operating Pressure: 300 psi Flow:

2000 GPM @ 4” Class 150 6600 GPM @ 6” Class 150

Minimum Flange Size:

4” Class 150 for a 4” sweep 6” Class 150 for a 6” sweep

Class I, Division 1 (Groups C and D) for Canada & USA

ATEX Zone 0 Certified Click here to view the 3D model

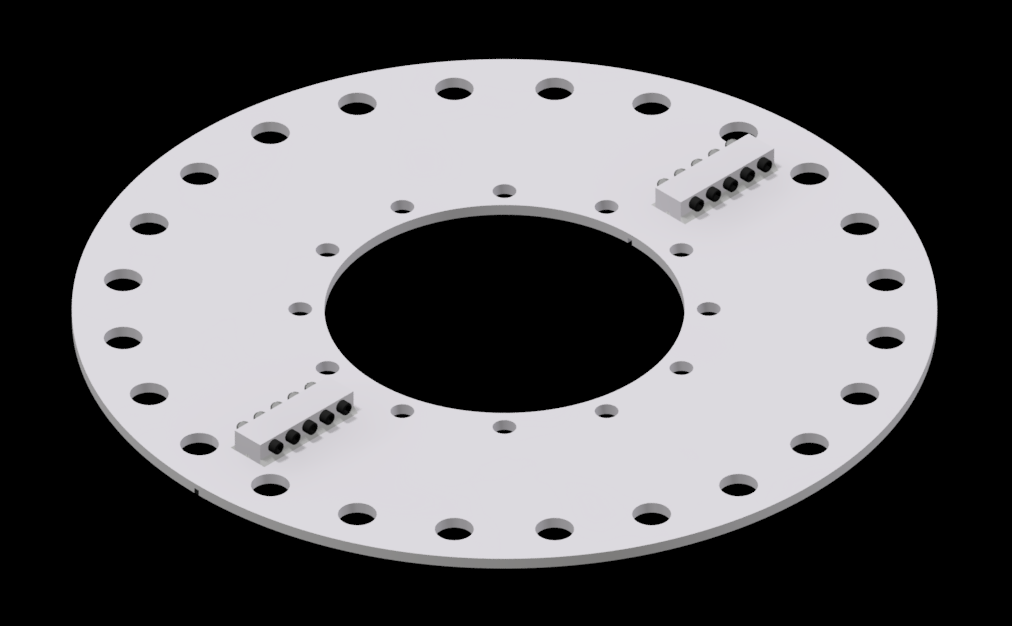

Split Flanges

Super-lightweight and split design, these flanges are specifically designed to reduce damages caused by sliding heavy adapter plates over top of your tools’ expensive instrumentation.

Available sizes:

18″, 24″, 36″, 48″ Class 150 size options.

18″, 24″, 36″, 48″ Class 300

20″, 24″, 30″, 36″ API

Click here to view the 3D Model