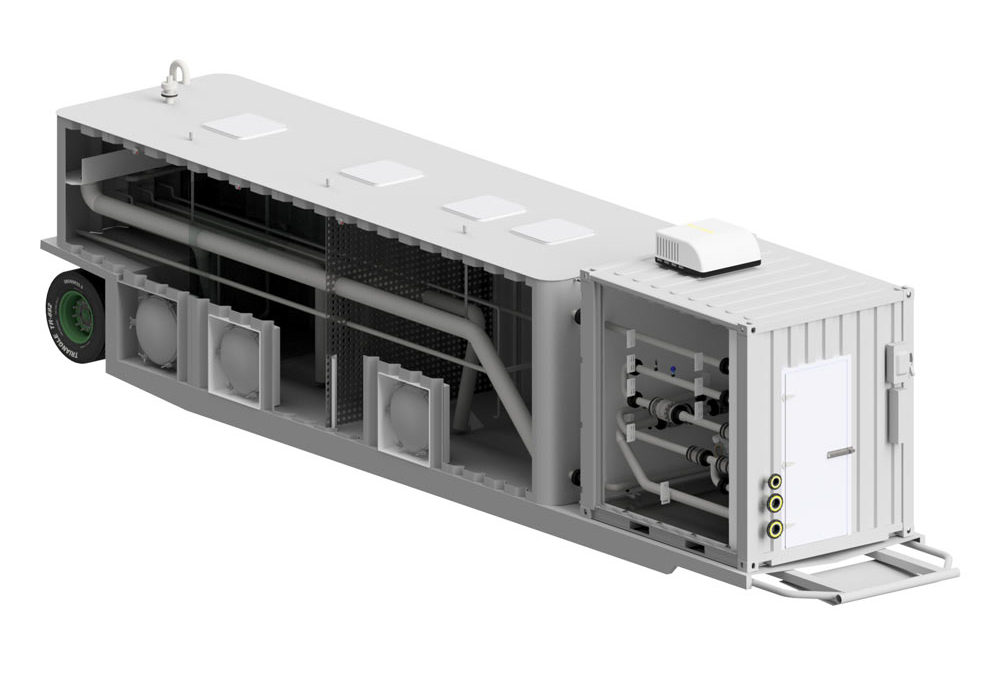

Radical Robotics is pleased to announce the introduction of their new innovative Circulation Management Tank (CMT), for use in the industrial tank and vessel cleaning industries.

This revolutionary new automated system is packed with features to help you maximize your circulation process and extract the largest amount of solids from the fluid in the shortest time.

The CMT ties seamlessly into the Radical Robotics circulation system while interfacing with the Radical Tank Sweeps and Radical Software’s VantageSuite. The new Radical Robotics CMT is a powerful tool you will want in your arsenal to get the most out of your circulation process.

Radical’s CMT is designed with two goals in mind: reduce downtime and maximize product recovery.

To that end, one of the most innovative features on the new CMT is the circulation bypass loop.

As fluid is pumped through the tank, special separation units demulsify the solids from the solution, storing them in specialized “knockout tanks.”

In most systems, the process must stop when these tanks fill up so that they can be emptied using a vac truck (or other means), bringing the entire project to a grinding halt, wasting valuable man-hours.

To avoid this problem, Radical’s system will automatically direct the flow of liquid into a bypass loop inside the CMT, while maintaining circulation and sending you a notification that it’s time for solids removal. Once the solids tanks are emptied, the loop reopens, and separation continues.

This ensures that even when the knockout tanks are full, the erosion process never stops, essentially eliminating downtime and maximizing the efficiency of the system.

During circulation, the CMT constantly feeds solids content and viscosity of the fluid into the Radical Software, allowing the software to continuously calculate and maximize flow rate, injection viscosity and heat to achieve the best possible erosion rate.

Plus, as the entire process is automated, it can run around the clock and requires minimal crew during operation.

During this whole procedure, the CMT continues to process product at a whopping 80m3 per hour, making it one of the fastest separation systems on the market.

It accomplishes all of this within a completely closed system, containing all tank vapours and giving you the option to tie in a scrubber for treatment if the job calls for it.

Like all Radical Robotics tools, the CMT requires minimal connectivity to function and can distribute power to the command centre and other Radical Robotics tools, making it easy to rig up and rig out.

Hydraulic lifting jacks make the tank simple to move around and transport. You’ll have the tank set up and running within hours of arriving on site.

Regardless of the size of your job, the Radical Robotics CMT is the best solution to maximize your circulation process.

For more information on the CMT, or to get a quote, contact Precise Tank Cleaning Tools Inc., the exclusive distributor of Radical Robotics products.